Technology

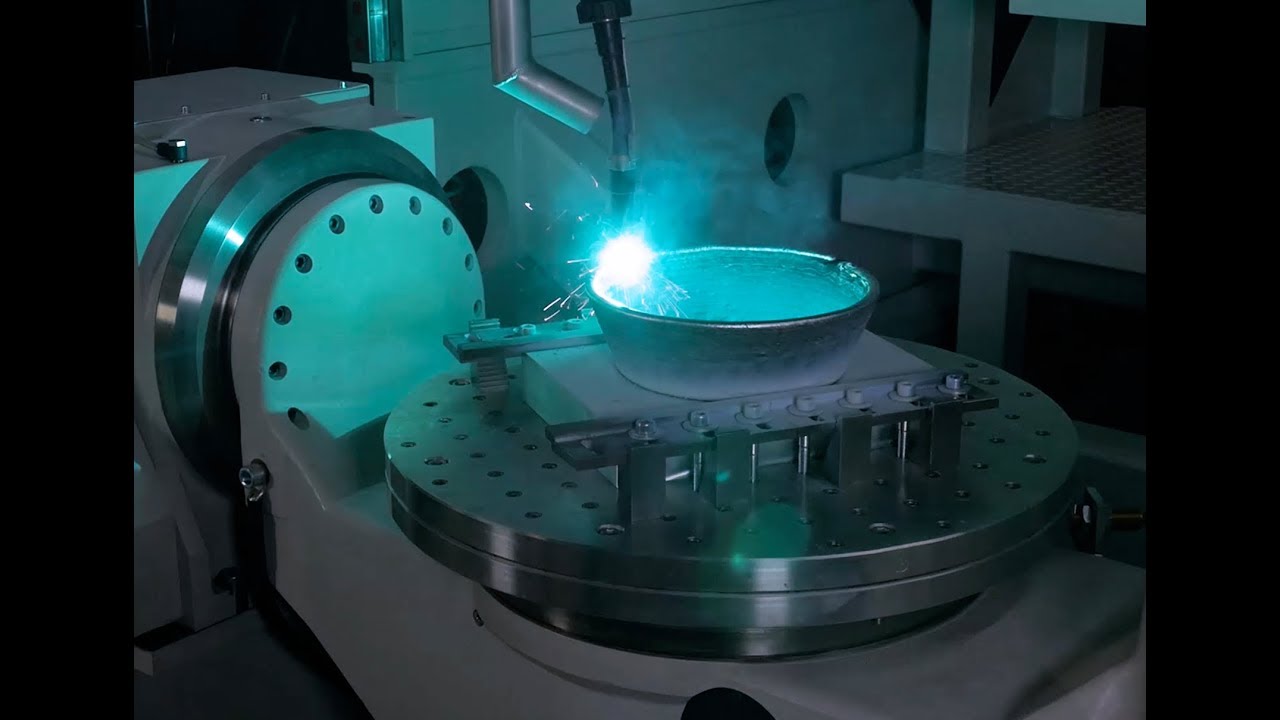

Wire Arc Additive Manufacturing (WAAM) uses welding wire to build large three-dimensional metal parts. By taking advantage of well-established manufacturing infrastructure and techniques, including welding robots, power supplies and auxiliary equipment, WAAM may be implemented relatively quickly and cost effectively. Arc welding has been known and developed since the 19th century.

Current Materials

Commercially available welding wire, including newly developed Aluminum 7XXX and 2XXX series alloys.

FAQ

- Uses welding wire readily available at competitive cost.

- Takes advantage of well-established welding technology, equipment and materials.

- High deposition rates.

- No chambers or powder beds needed.

- Three-dimensional large-sized components may be built.

- No need for de-binding, sintering or HIPing.

Rate is alloy and process dependent but measured in kilograms per hour. For some alloys and processes it can be almost 10 kg/hr.

It uses an electric arc to melt metal wire.

The process is done in open air with localized gas shielding as needed.

No, although welding wire of various alloys designed for WAAM are actively being developed.

Depends on the metal alloy but one can refer to the wealth of publicly available information on arc welding processes. These techniques were developed decades ago and continue to be researched.

Depending on the welding technique used, you can go down to about 2mm (5/64”) albeit at a significantly reduced deposition rate.

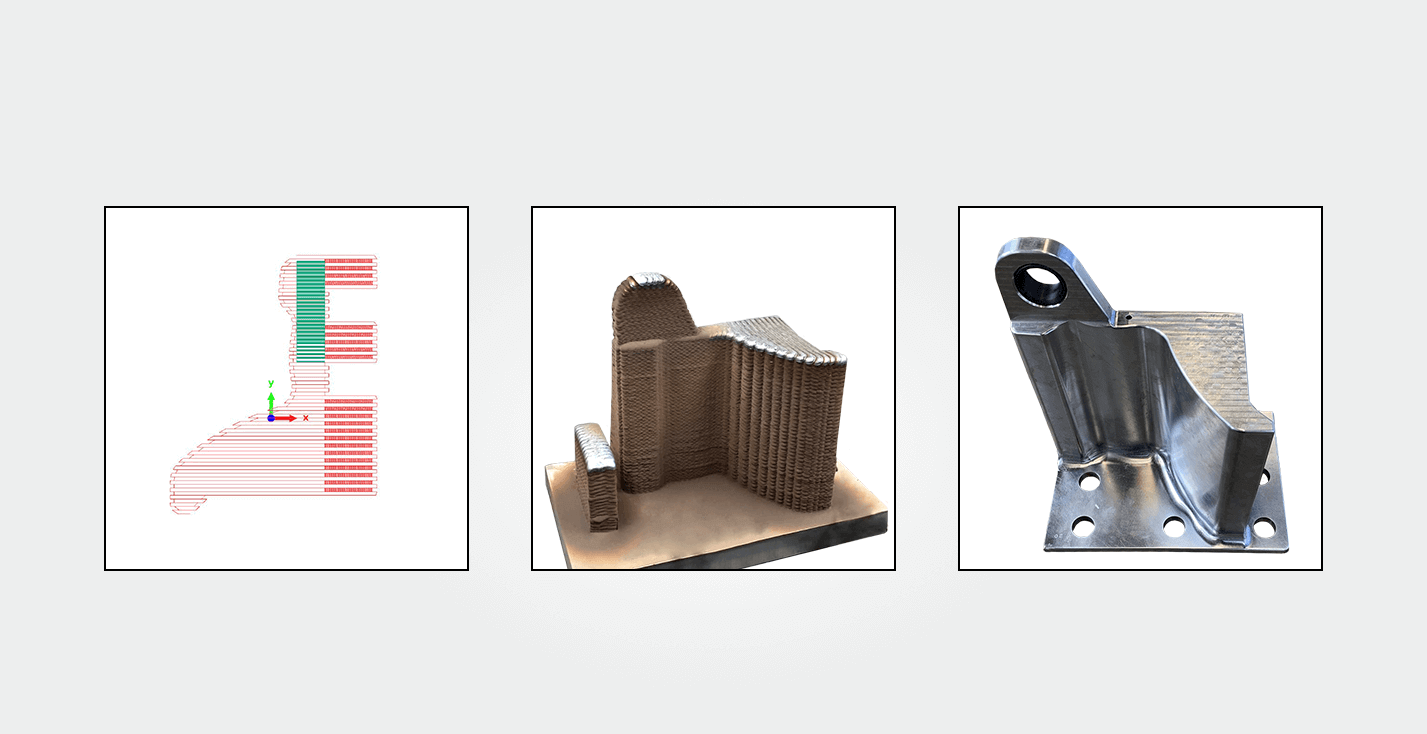

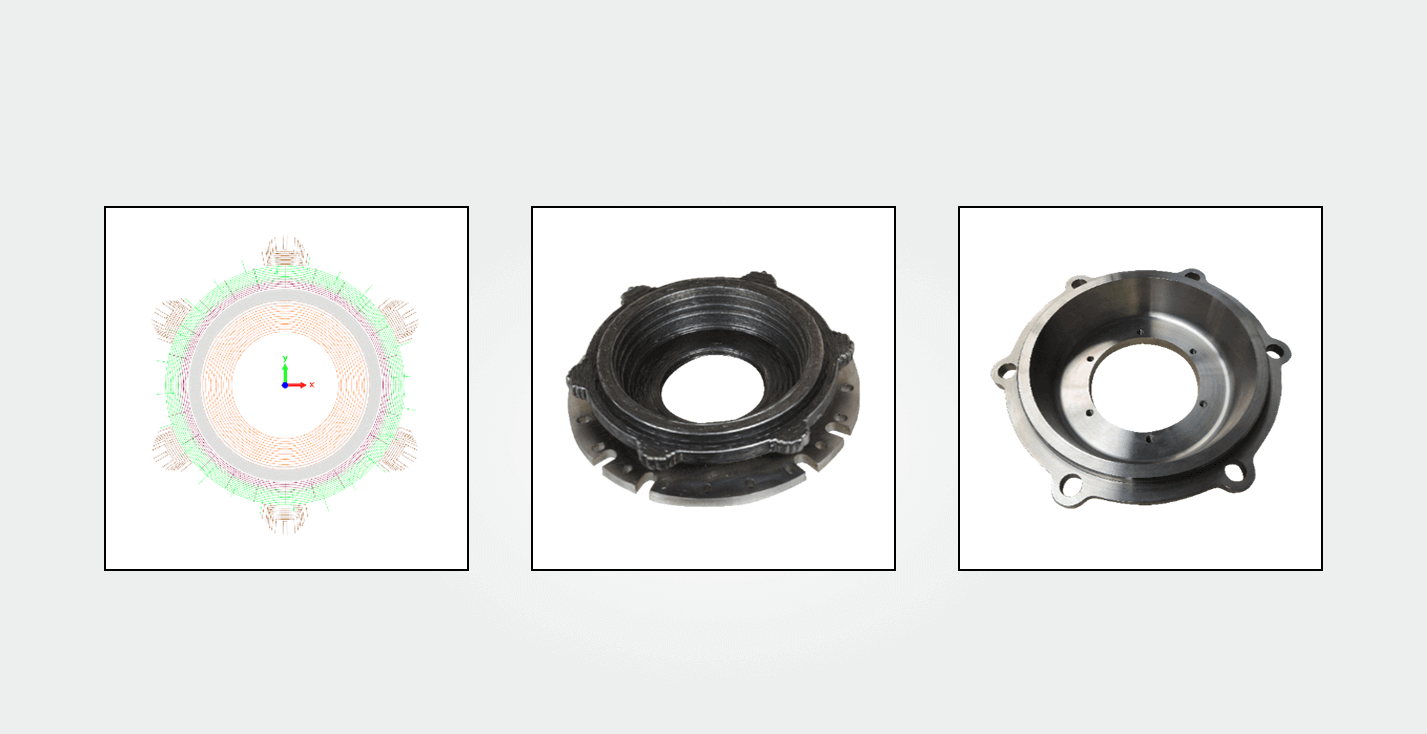

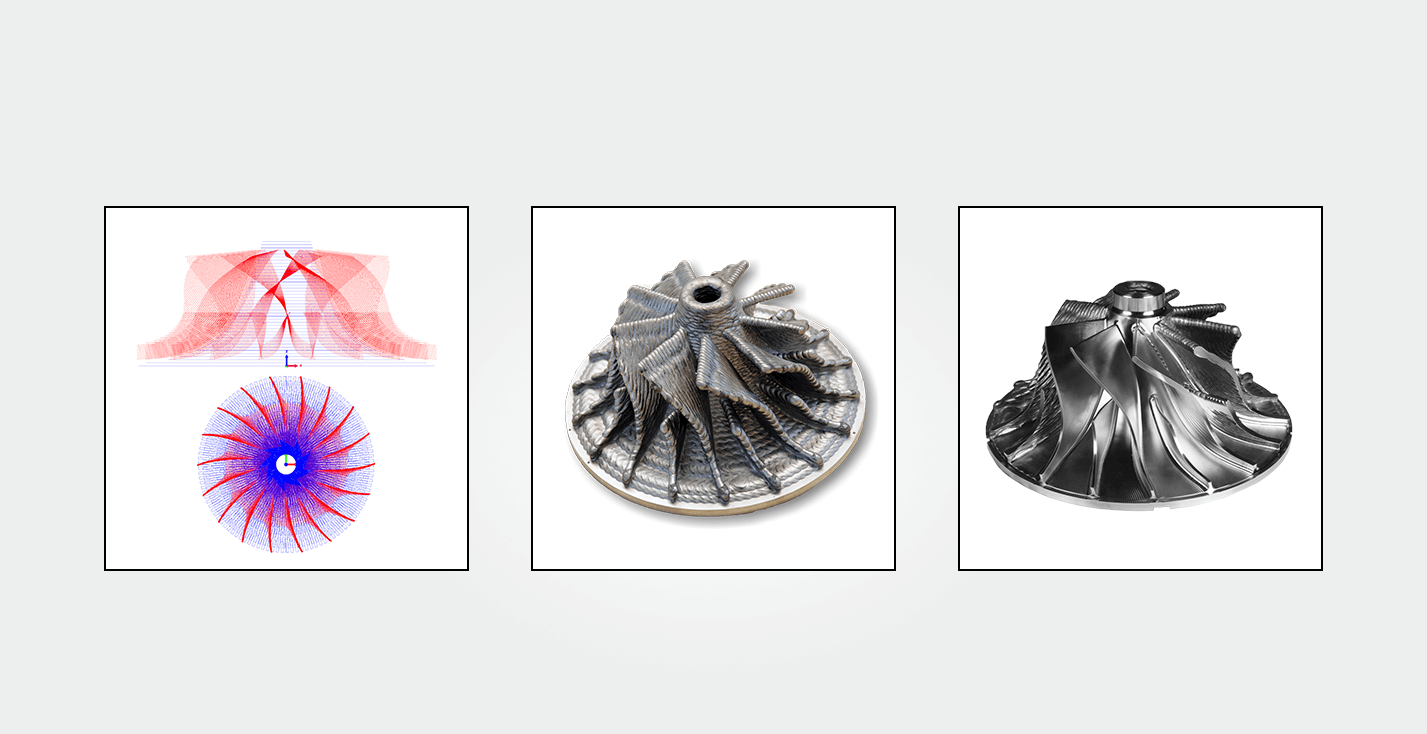

Featured Applications

Build semi-finished parts for raw material use

Obtain the metal parts you need as input for your manufacturing and production processes at the right time, in the right quantity and with the right size.

Build components used in structural applications

WAAM has been successfully used in mechanical, recreational and building components.

Research & Development

WAAM is an active field of research around the world:

- Cranfield University in the UK

- EWI in the US

- Facility for Intelligent Fabrication in Australia